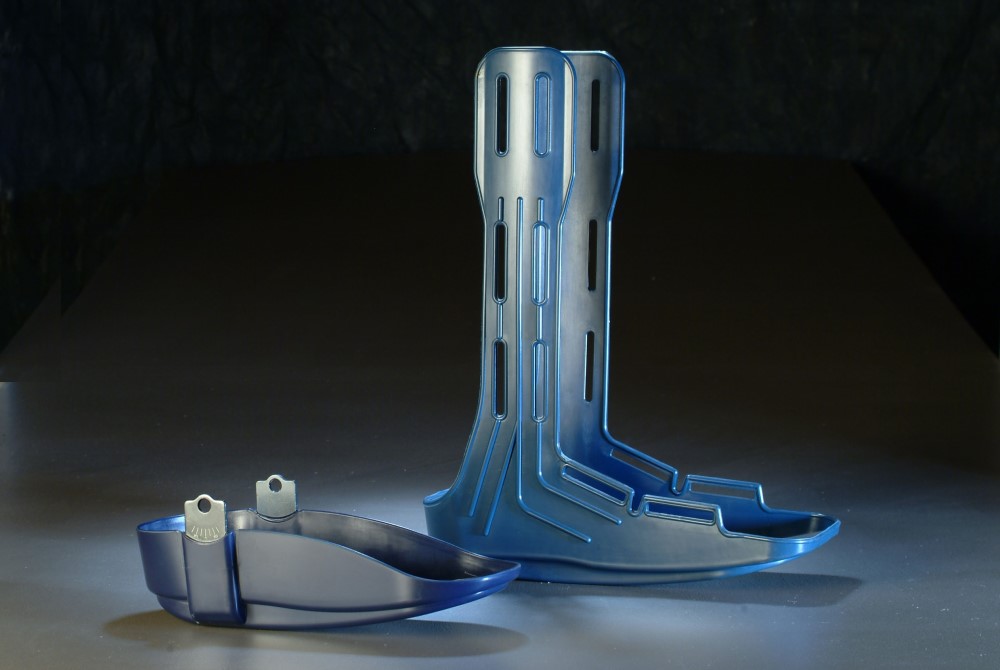

Transfer Molding Services

Thermoset Transfer Molding Process Overview

Transfer Molding is a method for molding thermoset materials where the design of the part is too complicated or unsuitable for compression molding. Transfer molding is often used when metal inserts, studs, connector pins, wear plates, electronic components, or other parts are molded into the part. The production steps include:

-

The mold is closed before the material is loaded

-

Thermoset material is placed into a heated “pot” connected to the mold cavity

-

The material is then “transferred” from the pot to the cavity under pressure from a hydraulic plunger

-

Material cures under heat and pressure to form a solid part

Key Considerations for Transfer Molding

-

Part complexity: Ideal for parts with intricate shapes, tight tolerances, and/or thin walls

-

Insert molding: Can encapsulate metal inserts or other components

-

Material behavior: Works best with thermoset materials that require controlled flow and cure conditions

-

Volume needs: Good for both low- and high-volume production

Get Transfer Molding Services for Your Industrial Application

Southwest Plastics provides manufacturers in aerospace, defense, electronics, medical, and other industrial sectors with superior plastic manufacturing solutions. With our industry-leading material expertise, advanced support services, and decades of experience, you can rely on Southwest Plastics for top-quality results for all your projects.